How to recycle tires?

How to recycle tires?

As the number of cars produced and driven around the world continues to increase, the number of end-of-life tires continues to increase every year.

What is tire recycling?

Tire recycling is the process of converting end-of-life tires that are no longer usable due to damage or wear into reusable materials.

Tires have a limited lifespan as damage can occur with regular use. Tread depth will decrease due to normal wear, and tires with a tread depth less than 1.6 cm will become unsafe. Hot summer temperatures, incorrect alignment and other factors can also damage tires, further limiting their lifespan.

Tire recycling does not treat end-of-life tires as waste, but rather as a resource for recycled materials. The material composition recovered from end-of-life tires includes 45% natural and synthetic rubber, 28% carbon black, 13% steel and 14% fabric and other tire additives.

How to recycle tires?

Material recycling, whole tire recycling and pyrolysis recycling are three ways of tire recycling.

Material recycling

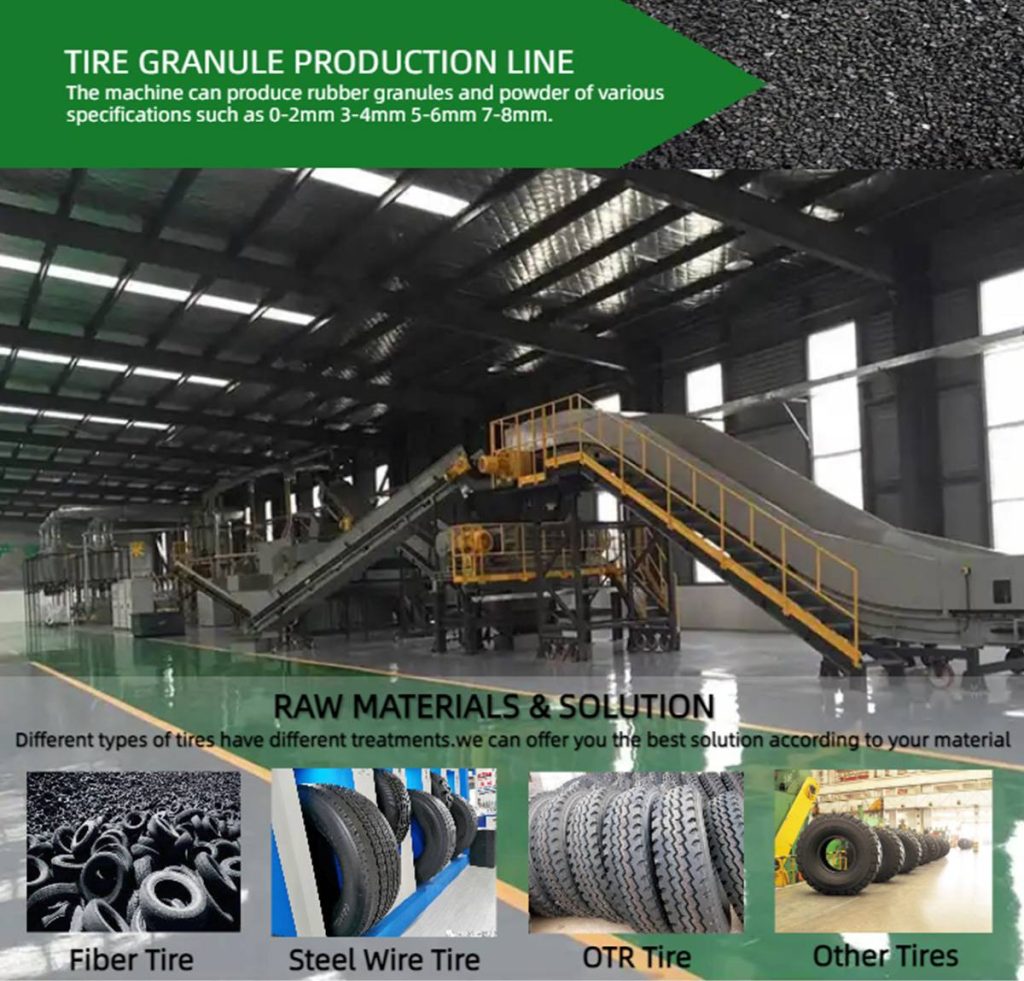

This is the most common tire recycling method. There are two technologies: grinding to produce particles and devulcanization to regenerate the rubber.

Grinding: This requires special equipment and the following steps:

The traveler and fabric separate before grinding begins. Steel wires need to be melted down before being reused; fabrics are cleaned before being used for energy recovery or as insulation.

There are two main methods of grinding scrap tires: normal temperature grinding and low temperature grinding.

Room temperature grinding relies on the use of mechanical equipment such as pulverizers and grinders. Repeated processing produces rubber particles with a required size of more than 0.3 mm and rough edges. Because the process generates heat, cooling must be performed to prevent combustion.

Cryogenic grinding uses liquid nitrogen to freeze the tire fragments to below -80°C. The hammer crusher crushes the brittle rubber to obtain small particles with a uniform size of 75µm, with a smooth surface and clean and sharp edges. Electromagnets remove steel filings and other processes remove fabrics. This rubber is purer but more expensive than rubber ground at room temperature.

The rubber particles are screened to ensure that there are no steel wires and other tire components. This stage is followed by classification based on particle size, and different sizes and types of particles can be used for different purposes.

Guanulate cleaning is the last process before Guanulate packaging.

Desulfurization: This process breaks down natural rubber by breaking the cross-links formed during vulcanization. Thermochemical, physical and biological desulfurization methods exist. But this process degrades the rubber polymer, resulting in the loss of many rubber properties.

Whole tire recycling

Civil engineering uses whole tires because of their shape, size, elasticity, stability and ability to dampen noise and impact vibrations. Tire chips of 50-300mm and tire granules of 10-50mm can also be used in civil engineering, such as the production of paving bricks/tiles, track and field and stable absorbing pads.

Hai Shi Hong has its own waste tire recycling process, we look forward to your inquiry!