Installation instructions for the shredder

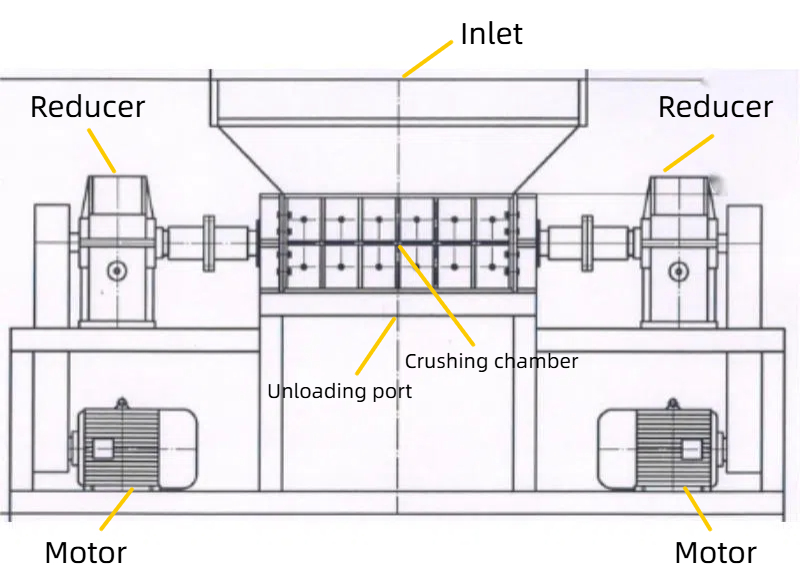

A twin-shaft shredder is a type of primary shredder that is used to process raw materials or leftovers, which can make the size smaller. Compared with other crushers, the speed is low, the noise is low, and the energy consumption is low. If used incorrectly, the shredder will not work properly. However, for the shredder, the correct use method can not only effectively avoid these failures, but also improve the service life of the blades, so the correct use of the shredder is extremely important.

Installation instructions

- The machine can be placed on a stable cement ground

- When the shredding machine is installed, we must pay attention to avoid the sun and rain

- The line should be prepared in time

- During installation, there must be a solid and reliable concrete foundation. During operation, there should be no obvious vibration, and the direction of rotation should be identified before normal production can be carried out

- Fixation is required during installation to ensure that no looseness occurs

- The installation of the machine should be fixed to ensure that there is no looseness, this phenomenon may be ignored by many people and feel that there is no impact, but the result is just on the contrary, the big problem is caused by small problems. If the machine needs to be fixed but not fixed, long-term production can easily make the shredder unstable, long time will cause increased vibration, eventually lead to increasing noise of the machine, and easy to cause damage, so we have to fix the machine to ensure long-term normal operation.

- After installation, it is not allowed to move the shredder arbitrarily: although the body has safety protection components, moving the shredder arbitrarily may still damage the metal cover, electrical box, bracket and other components of the shredder

Emergency Processing Program

- When a sudden power outage occurs, after powering on, follow the startup program to start without load.

- Before running the shredder, grease must be added. The amount of grease added to the bearing seat should ensure that there is 1/3 of the grease in the bearing cavity. Excessive grease can cause poor heat dissipation and bearing damage, while too little grease can cause poor lubrication of the bearing.

Operational safety

During installation, operation, and maintenance, in order to avoid personal injury and shredder malfunction, please provide the following safety education to the personnel:

- Location of shredder: During daily maintenance of the shredder, staff must ensure that there is sufficient space to complete the work. Sufficient operating space can ensure that staff avoid accidents in a timely manner.

- Safe working environment: When the shredder is running, ensure that the operating area of the grinder is clean and keep maintenance tools in time. Falling maintenance tools into the shredder can cause serious damage to the machine.

- Wearing glasses or safety masks: Although the shredding machine box is designed to prevent material reflux to the greatest extent, to avoid accidents, operators must wear glasses or safety masks when operating near the hopper.

- When operating the shredder, it is strictly prohibited to wear loose clothing and any hanging objects such as jewelry, ties, belts, etc; Long hair must be tied up or coiled inside a safety helmet; When feeding materials, it is strictly prohibited to reach into the feeding hopper with your hands to feed.

- Motor rotation: The direction of rotation is clearly marked on the motor, and operators must conduct routine checks on the direction of rotation. Wrong direction will seriously damage the shredder

- Before using the shredder, make sure to lock the power supply of the shredder switch.

- The principle for starting the shredding system is to first use peripheral equipment before the main equipment, and then use auxiliary equipment before processing equipment.

Matters needing attention

- Before using the shredder equipment, stabilize the equipment and power facilities to prevent leakage or rain. It is strictly prohibited for personnel under the age of 16 to operate this machine.

- In order to ensure the safety and normal operation of personnel and the machine, a dedicated person should be designated to be responsible for the storage and use of the machine. It is not allowed to operate the machine without learning this procedure and operating techniques.

- Check if the screws at the joint are loose, and tighten them in a timely manner if any looseness is found.

- It is strictly prohibited to remove the feeding hopper and directly feed the material. The equipment configuration is based on the actual situation of the user's materials. Materials that do not meet the requirements are strictly prohibited from entering the crushing bin.

- During maintenance, ensure that the main power supply is disconnected and a warning sign is hung or a dedicated person is assigned to guard the power supply; It is strictly prohibited to work with electricity on all matters.

- Electric motor and coupling: Users should install safety protection facilities according to their own material and environmental requirements; Do not arbitrarily increase the spindle speed, and do not dismantle the protective devices of various parts.

- If abnormal noise occurs during operation, the machine should be immediately stopped for inspection. Do not troubleshooting when the machine is running.

- According to the actual use, regularly add the main shaft grease, and regularly check the reducer gear oil. It is strictly prohibited to work without oil.