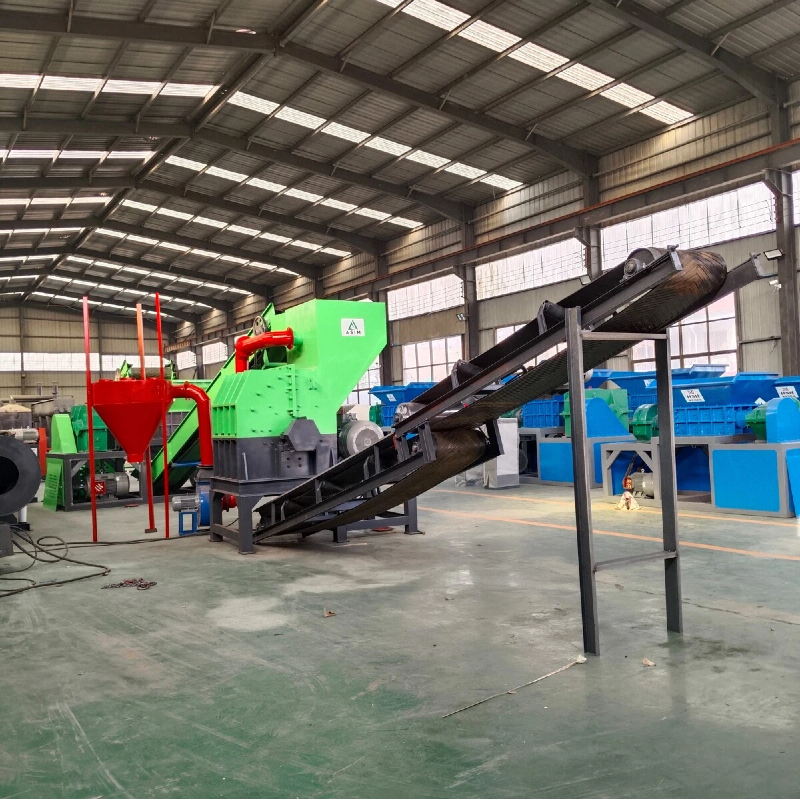

Metal Shredding and Crushing Production Line: Helping Enterprises to Efficiently Process Metal Waste

In today's industrial production, the disposal of metal waste has always been a headache. On the one hand, a large amount of metal waste is piled up, which not only occupies space, but also poses a potential threat to the environment; on the other hand, if these metal wastes can be effectively recycled, it will bring considerable economic benefits for enterprises. The emergence of metal shredding and crushing production line is like a magical key, which opens the door for us to process metal waste efficiently.

First, the role of metal shredding and crushing production line

The metal shredding and crushing production line is mainly used to shred and crush metal wastes of various shapes and sizes. Whether it is waste automobiles, waste home appliances, waste metal pipes, or other kinds of metal product wastes, they can be easily shredded into small pieces by this production line for subsequent recycling. For example, some large-sized scrap cars can be shredded into fist-sized metal pieces through the metal shredding and crushing production line, which greatly reduces their size and facilitates transportation and subsequent processing procedures such as smelting.

Second, the benefits of metal shredding and crushing production line

- Improve the utilization rate of resource recycling

The metal shredding and crushing production line can effectively crush metal waste that is originally difficult to handle, making it easier to recycle. This not only reduces the waste of metal resources, but also saves a lot of raw material procurement costs for enterprises. Take a scrap metal recycling enterprise as an example, through the use of metal shredding production line, its metal recycling utilization rate increased by more than 30%, saving hundreds of thousands of dollars in raw material costs for the enterprise every year. - Reducing environmental pollution Traditional metal waste disposal methods, such as landfill or incineration, can cause serious pollution to soil, air and water. While the metal shredding and crushing production line can crush the metal waste in a closed process, effectively reducing the emission of dust and harmful gases. At the same time, the crushed metal waste can be recycled, avoiding the environmental pollution problems caused by landfill or incineration.

- Space saving Metal waste is usually large in size and occupies a lot of storage space. The metal shredding and crushing production line can shred these wastes into small pieces, greatly reducing the space it occupies. This is undoubtedly a huge advantage for some enterprises with limited space. For example, a small scrap metal recycling station, through the use of metal shredding and crushing production line, its storage space utilization rate increased by more than 50%, effectively solving the problem of insufficient space.

- Improve work efficiency The metal shredding and crushing production line adopts advanced automation technology, which can realize continuous and efficient shredding and crushing operations. Compared with the traditional manual processing methods, its work efficiency is greatly improved. Take the processing of waste household appliances as an example, the traditional manual dismantling and crushing method can only deal with dozens of waste household appliances every day, while the metal shredding and crushing production line can deal with hundreds of waste household appliances every day, which greatly improves the work efficiency.

Third, the application of metal shredding and crushing production line scene

Metal shredding and crushing production line is widely used in many fields such as scrap metal recycling, scrap car dismantling, waste home appliance processing, metal product processing and so on. In the waste metal recycling industry, it can shred and crush all kinds of waste metals, which is convenient for subsequent classification and recycling; in the waste car dismantling industry, it can quickly shred the metal parts of waste cars and improve the efficiency of dismantling; in the waste home appliance processing industry, it can crush the metal shells etc. in waste home appliance, which realizes the recycling and utilization of resources; in the metal products processing industry, it can crush the edges and corners produced in the production process and return them to the furnace for smelting again, which reduces the raw materials. In the metal products processing industry, it can crush the edges and corners produced in the production process and return them to the furnace for smelting, reducing the waste of raw materials.

Fourth, the choice of metal shredding and crushing production line recommendations

In the choice of metal shredding and crushing production line, enterprises need to be based on their own production needs and budget for comprehensive consideration. First of all, to determine the processing capacity of the production line, to ensure that it can meet the production needs of enterprises; secondly, to consider the degree of automation of the production line, a high degree of automation of the production line can improve efficiency and reduce labor costs; finally, we also need to consider the after-sales service of the production line, and choose a good after-sales service manufacturers, can be in the equipment failure to get timely maintenance and repair to ensure that the production of normal.

The emergence of metal shredding and crushing production line has revolutionized the treatment of metal waste. It not only improves the utilization rate of resource recycling and reduces environmental pollution, but also saves space and improves work efficiency. With the increasing awareness of environmental protection and the growing importance of resource recycling, metal shredding and crushing production line will be widely used in more enterprises, creating more economic and environmental benefits for enterprises.