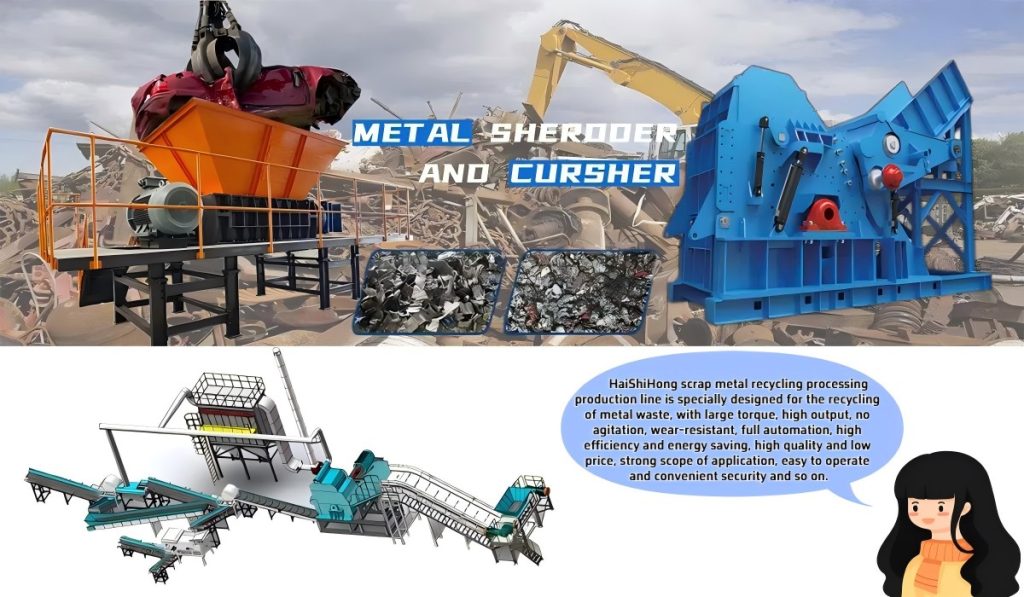

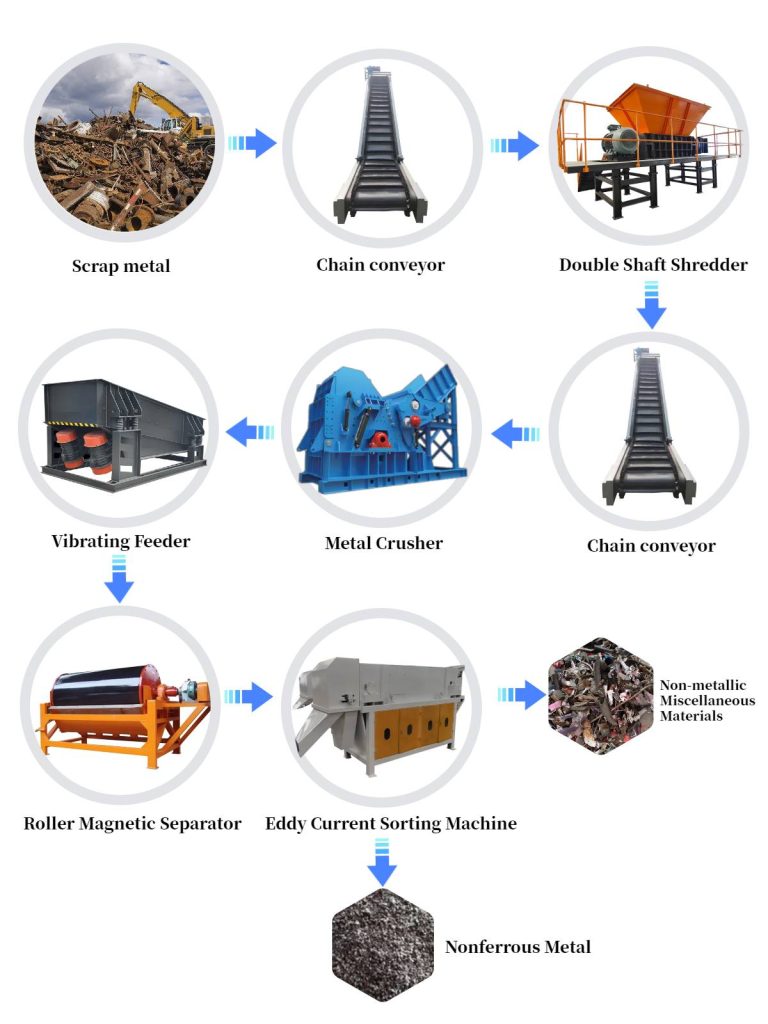

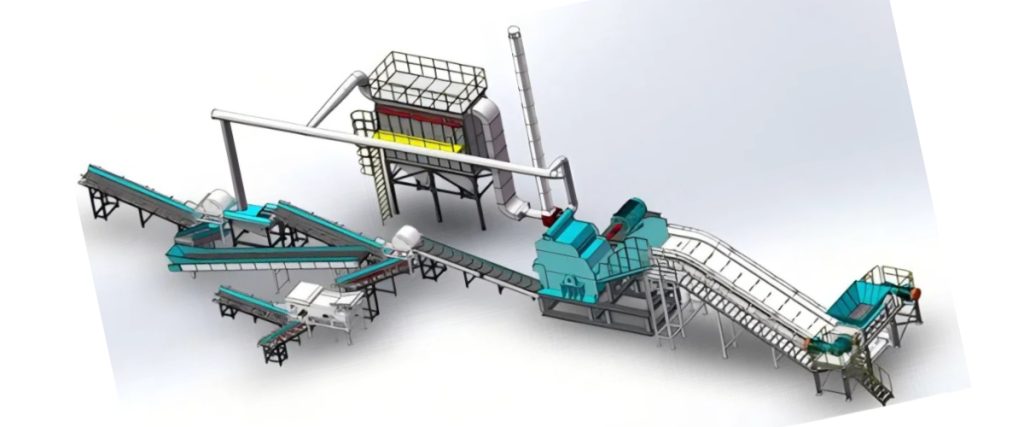

Scrap Metal Recycling Plant Waste Scrap Car Aluminium Steel Recycling Line System

pplicable Materials:Automobile shells, Scrap aluminum, Scrap steel, Scrap metal, Paint buckets, Color steel tiles, Iron briquettes, Motorcycle racks, Bicycle racks, Scrap home appliances, Carriage boards, Keel bars, Rolling shutters, Scrap angle iron, scrap iron. etc.