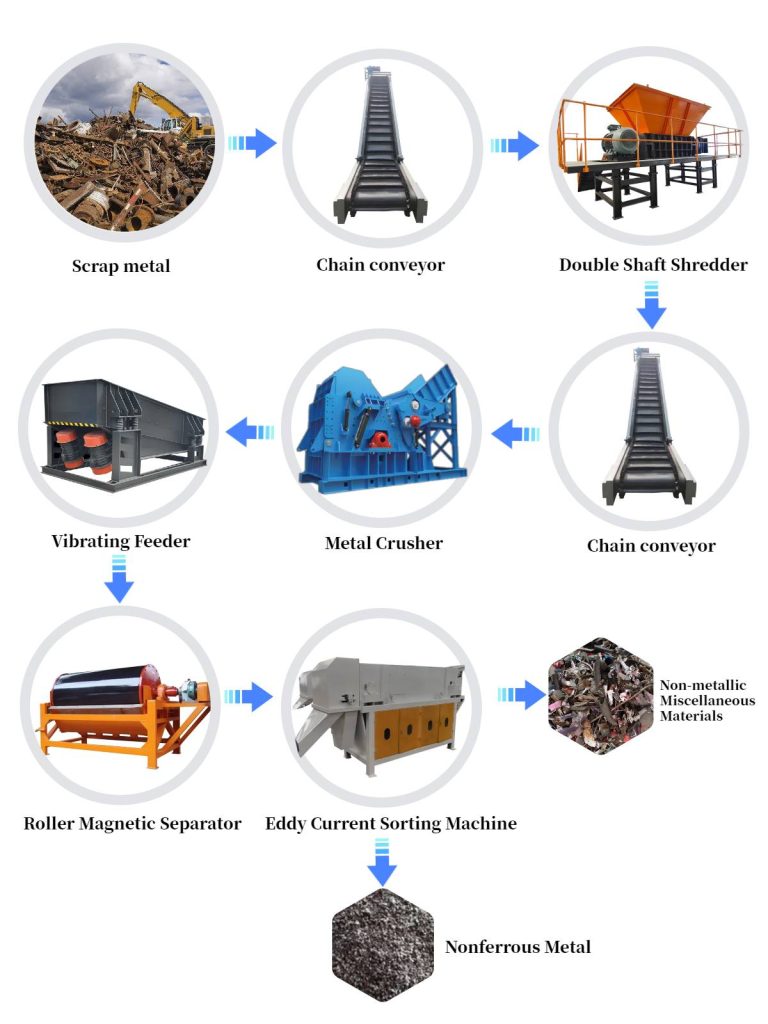

Scrap Metal Sorting and Recycling Production Line

Introduction

Since metals such as aluminum, steel and copper can be recycled indefinitely without degradation, the recovery and processing of scrap metal is essential to building a sustainable future. Metal recycling reduces primary production, conserves natural resources and significantly reduces energy consumption. With outstanding technology in the field of metal recycling, our high-performance sorting systems eliminate contamination and meet even the most stringent purity and quality requirements worldwide.

Our scrap metal sorting and recycling lines can efficiently process e-waste, various profiles, automotive shredding residue ASR, etc., ensuring maximum recycling of various ferrous and non-ferrous metals.

Aluminum recycling

Aluminum is a continuously recyclable material that requires only 5% of the energy used to produce primary aluminum. As industries focus on sustainable manufacturing and CQ2 emissions, global demand for recycled aluminum continues to surge. Our recycling systems enable high-throughput sorting of aluminum alloys from post-production and post-consumer scrap metal. Our high-performance sorting equipment effectively separates aluminum and aluminum alloys from heavy metals. Whether sorting castings, forgings, sheet metal, or producing aluminum fibers that can be used in prefurnace applications, our equipment delivers excellent sorting results.

Copper

Copper is a fully recyclable material and is an important raw material for global supply chains, particularly in the electronics industry. From printed circuit boards to cables and wires, the recovery of copper from e-waste is critical to meeting the growing global demand for recycled copper and helping to conserve this non-renewable natural resource. Copper recycling is an important and efficient source of secondary raw materials for the global supply chain. In addition to significant environmental benefits, recycled copper requires 85% less energy than primary production. Copper is fully recyclable and is found in end-of-life products such as pipes, appliances, electronics, wires and building materials. Our sorting equipment excels at detecting all types and particle sizes of copper objects found in complex electronic waste streams. Using highly sensitive sensors, contaminants such as lead can be detected by characteristic and color changes. Your operation profits from high-purity copper particles to meet market demand.

E-waste metal recycling

E-waste is one of the fastest growing waste streams in the world, expected to reach 74 million tons by 2030. Sensor-based classification of electrical waste and electronic equipment (WEEE) recovers valuable materials such as metals and plastics for recycling. It also ensures that hazardous components such as brominated flame retardants are handled properly.

Automated sorting of mixed metals enables e-waste recyclers to achieve a significant return on investment through the recycling and sale of high-purity aluminum, copper, gray metals and brass. Printed circuit boards and thermoplastics can also be efficiently sorted into clean portions for marketable products.

End-of-life vehicles

End-of-life vehicles are a valuable source of secondary raw materials, including mixed metals. From body parts to components and electronics, sensor-based metal sorting systems effectively detect, separate and purify the wide range of non-ferrous metal fragments found in automotive shredding residue (ASR). Our versatile sorting units remove typical contaminants such as polymers, wood and glass, resulting in higher purity and metal recovery rates. With state-of-the-art sensor technology and intelligent object recognition, you can benefit from high-quality clean fractions of pure metals such as aluminum (twitch, forged), copper and brass.