The application of metal shredder reduces the waste of metal resources

In years gone by, people used to pile up scrap metal in a corner without planning or dispose of it directly in landfills. As a result, limited resources were wasted and the environment was inevitably polluted. Generally speaking, scrap metal covers a wide range of materials such as copper, aluminum, steel, stainless steel and so on. The source of these scrap metals is very wide, the construction of the construction process in the field of large quantities of scrap metal parts, industrial production lines down the elimination of all kinds of metal products, home life in the replacement of metal objects, as well as the electronic industry in the replacement of the discarded metal components, etc., are its important source. Scrap metal recycling is undoubtedly a key and indispensable part of the environmental protection industry. Its core purpose is to fully utilize these originally discarded metal materials, through the scientific and reasonable recycling process and technical means, to minimize the waste of resources caused by improper handling of scrap metal, and effectively reduce the serious pollution caused by the environment, so as to build a resource-saving, environmentally friendly society to contribute.

In today's era, with the environmental protection concept continues to deepen the hearts of the people and the sustainable development of resources strategy to vigorously promote the recycling of scrap metal has become a crucial task. In order to achieve this goal, an excellent performance in the industry equipment -- HaiShiHong metal shredder came into being, and in many related fields has been widely used.

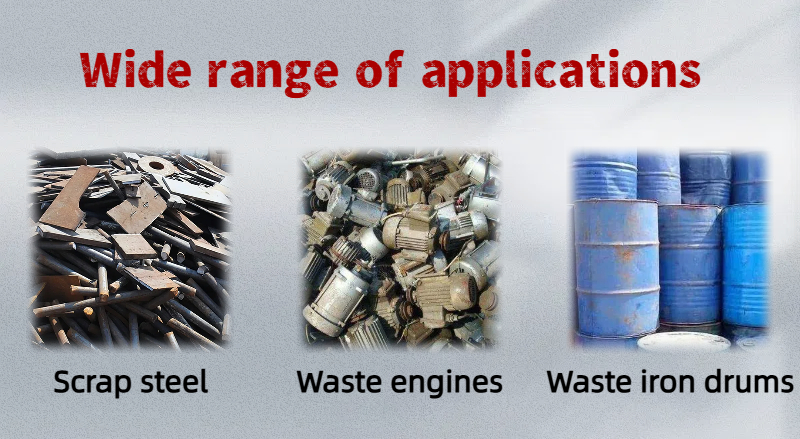

Hai Shi Hong metal shredder has a very wide range of applicability, its figure often appears in all kinds of scrap metal material processing site. Take the car shell, in the automobile end-of-life treatment process, those discarded car shell volume is huge and hard texture, and the sea Shihong metal shredder can rely on its strong mechanical properties, easily and gradually shredded decomposition, so that it is converted into metal fragments for subsequent processing. For metal briquettes, whether after preliminary compression processing of small metal briquettes, or large, very high density metal waste briquettes, the equipment can be methodically crushed operation, the original tight metal briquettes re-breaking into loose metal particles or fragments. Look at thin iron such as thin but with a certain toughness of scrap metal materials, HaiShiHong metal shredder is also able to accurately deal with it, through the unique mechanical structure and mode of operation, will be thin iron cutting, tearing into the recycling requirements of the specifications.

The reason why this Hai Shi Hong metal shredder can stand out in the market, favored and praised by many users, the key lies in its own has a series of unique and excellent characteristics. It adopts advanced low-speed, high-torque design concept, this low-speed operation mode effectively reduces the wear and tear of the equipment in the process of operation and energy consumption, greatly extending the service life of the equipment, but also reduces the potential safety hazards that may be brought about by high-speed operation. The large torque gives the equipment powerful tearing and crushing power, which makes it able to handle different textures, hardnesses and shapes of scrap metal materials with ease. In addition, during the operation of the equipment, it also shows a very low noise level, compared with the traditional metal processing equipment, the noise generated by the decibel number is greatly reduced. This feature makes it in urban environments or higher noise requirements of the work area can also be used normally, will not cause too much noise interference to the surrounding environment and staff. In addition, HaiShiHong metal shredder also has impressive high output performance, it can handle a large number of scrap metal materials in a unit of time, greatly improving the efficiency of the recycling of scrap metal processing, saving a lot of time and labor costs for the enterprise, so as to provide a strong equipment for the efficient operation of the entire scrap metal recycling industry.

This equipment is widely used in the recycling treatment of scrap steel, scrap iron, scrap car dismantling and other metals. It mainly utilizes the shearing force of the rotating movable knife and the fixed knife to shred the scrap metal into small pieces. Because the scrap metal shredder is equipped with multiple sets of blades inside, the gap between the blades will form spacing. So when the material enters the machine, it is subjected to the shearing and tearing effect of the rotating blades, and is gradually shredded into small pieces. The shredded metal pieces can then be screened and classified for subsequent smelting and reuse.