Tire recycling and processing line

Introduction

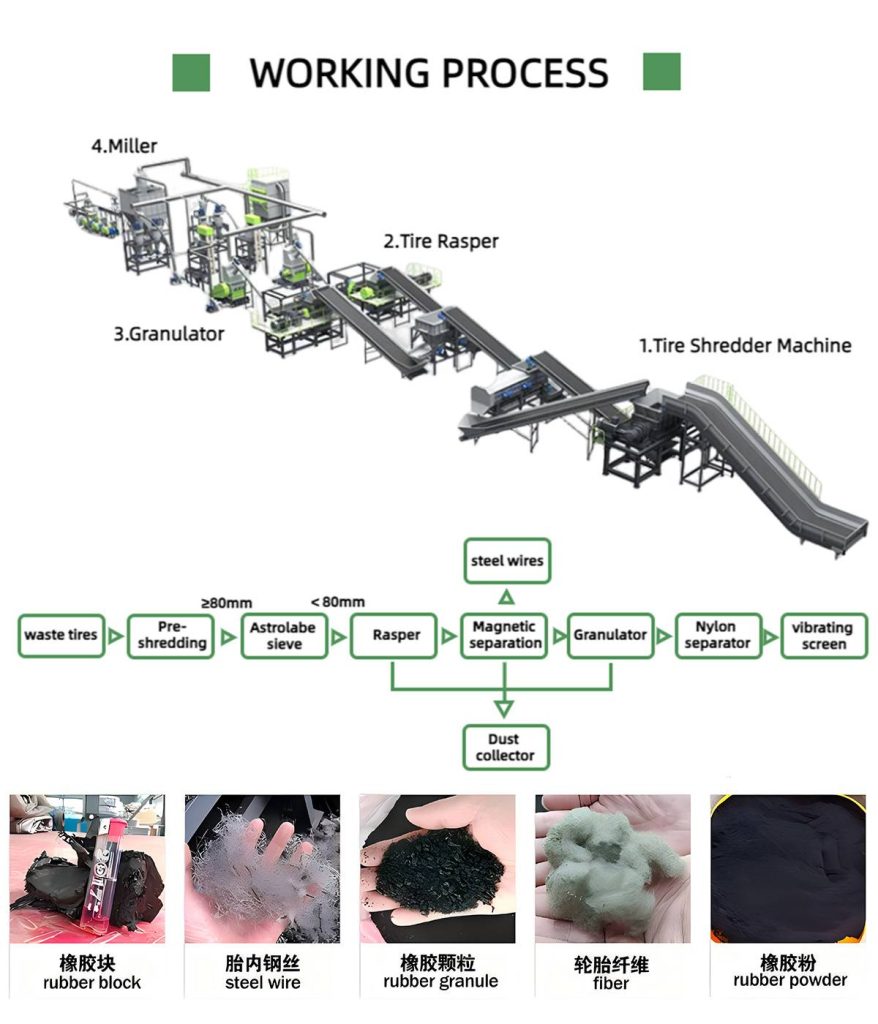

The tire recycling and treatment production line designed by the company contains disposal equipment such as tire shredding, steel wire separation, iron removal, fiber separation, etc. Deep processing equipment such as granulators, rubber breakers, mills, etc. can also be added, and the automated operation of the whole system is realized through an intelligent management system.

The world produces waste tires every moment, which come from family cars and various work vehicles. Composed of rubber, steel, carbon black, and a variety of chemicals, scrap tires are also known as “black gold mines,” and their recycling is a well-established and lucrative business. Tire-derived fuel (TDF), crumb rubber, rubber powder, and cracked oil refining from used tires are a few representative recycling applications.

The professional and reliable tire recycling and processing line designed by the company can help users to obtain higher purity rubber powder, rubber granules and steel wires through shredding, steel wire separation, iron removal, fiber separation and other dispositions of various types of waste tires (car tires & truck tires, bias tires & radial tires, pneumatic tires & solid tires, ≤800mm small car tires & ≥900mm large car tires), which is a more profitable business than selling waste tires directly. The system can help users obtain higher purity rubber powder, rubber granules and steel wires, which is more profitable than selling waste tires directly.

The system is fully combined with the actual experience of waste tires disposal for improvement, the design structure is more compact, high production and low consumption, low noise, intelligent, the back end can be configured with granulators, rubber breakers, mills and so on, to meet the different product manufacturing needs. Whether you have just started the tire recycling business or need to expand your production scale, we can design the rationalized disposal system and equipment for you according to your actual situation.

Resourcing programme

(1) Crushing and grinding: complete scrap tires are removed from non-rubber impurities (nylon fibers, steel wires) through the processes of extraction, crushing, sorting and grinding, so as to obtain pure rubber powder with different particle sizes.

(2) Cracking pre-treatment: After pre-treatment and crushing into pieces, waste tires are sent to thermal cracking reactors, where they are respectively made into combustible gases used as fuel oil and power generation, as well as carbon black, which is more expensive in the market.

(3) Making TDF: The calorific value of waste tires reaches more than 8,000 kcal, which is higher than that of coal burning at 5,000 kcal. Cement factories, power plants, iron and steel mills and smelters in many countries around the world use crushed waste tires as fuel to reduce the cost of corporate production. (See the case below or consult us for the physical picture)

Program Advantages

1.Double shaft tire shredder for tire crushing is our company's product with good processing effect;

2.The system adopts the mode of crushing and screening at the same time, with higher processing efficiency;

3.According to different discharge particle size requirements, can be combined with steel wire separator, rubber breaker, granulator, fiber separator, milling machine and other equipment, flexible production line configuration;

4.Intelligent detection system can assist the automatic operation of the production line, saving manpower and time, and improving the stability of the system.