What are the equipment in waste tyre crushing and grinding production line?

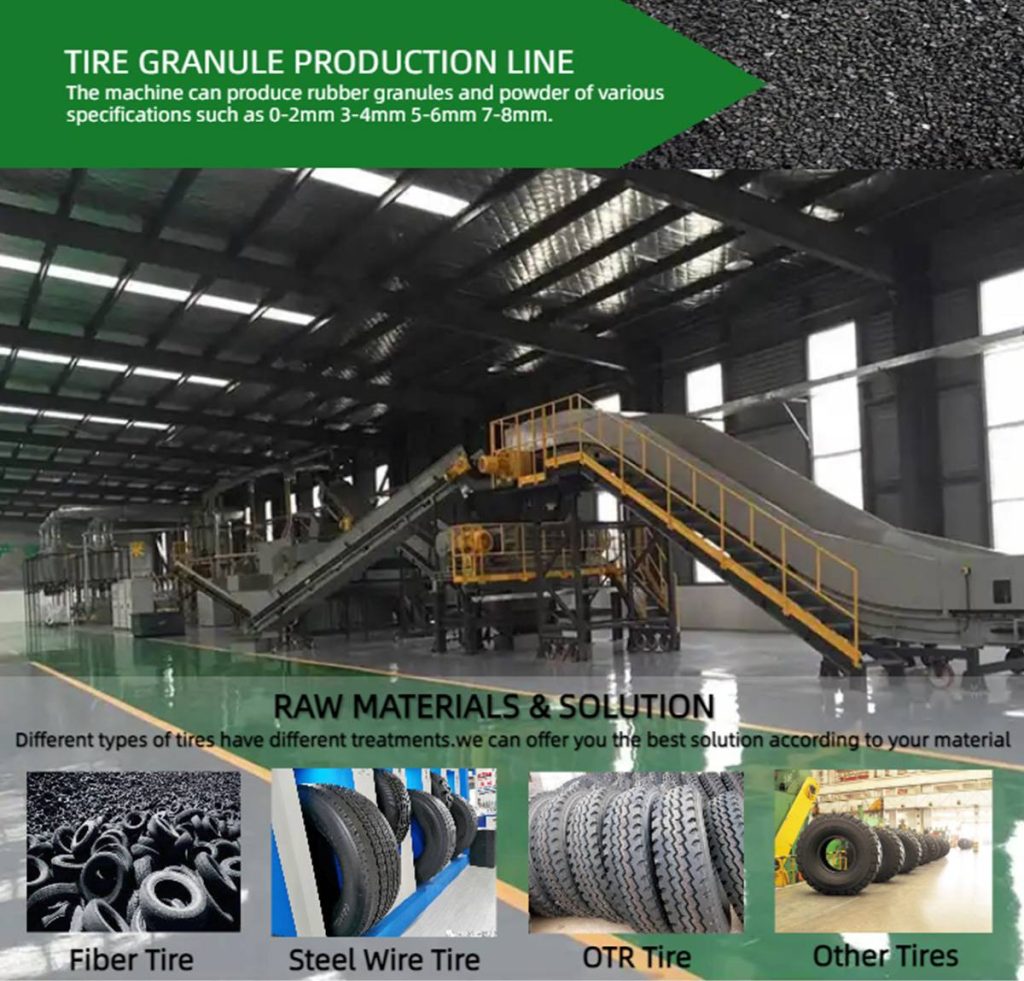

Waste tyre crushing and grinding production line mainly consists of main equipment such as tyre extractor, tyre shredder, rubber breaker, rubber grinding machine and other auxiliary equipment such as belt conveyor, screening machine, magnetic separator, fibre separator and so on.

Tyre Extractor:Tyre extractor is a patented equipment for pilling out large strands of steel wire from both sides of the tyre at one time and smoothly separating the steel wire and rubber, which facilitates the subsequent tyre crushing operation.

Tyre Shredder: The twin-shaft tyre shredder integrates high-efficiency crushing and ring drum screening in one machine. With unique tool design and arrangement structure, it achieves precise crushing and instant screening of tyres, improves processing efficiency and simplifies operation process, and is an innovative equipment specially developed for the fields of pre-processing of tyre cracking, preparing raw materials for combustion power generation, and fine crushing and recycling.

Rubber Breaker: Rubber breaker is the equipment to further crush and grind the rubber block after rough crushing, with the function of fine crushing and separating steel wire and rubber.

Rubber mill: rubber mill is a kind of special equipment that can grind rubber particles with feed specification of 15-25 mesh (without steel wire and other high hardness impurities) into fine rubber powder of 40-60 mesh at one time under normal temperature. If the feed specification is 60-80 mesh, the output is 80-120 mesh super fine rubber powder. The grinding range can be adjusted according to the user's demand for rubber powder particle size.

Belt Conveyor: Belt conveyor uses the continuous or intermittent movement of conveyor belt to convey loose materials below 100kg, which has the features of strong conveying capacity, long conveying distance, smooth and reliable delivery, convenient disassembly and assembly, easy maintenance, low cost and so on.

Sieving machine: The sieving machine is designed for efficiently sieving powdery or granular dry materials. The machine adopts multi-angle vibration source, the material undergoes multi-dimensional vibration in the screening process, and is accurately divided into several different particle size levels to meet diversified production needs.

Magnetic Separator: With the powerful magnetic field energy and magnetic induction strength released by its magnetic rollers (or magnetic cylinder), the magnetic separator becomes the key equipment for separating steel wire and purifying rubber in the processing of rubber tyre crushing.

Fibre Separator: Fibre Separator is an air sorting machine that separates the fluffy fibres mixed in the rubber granules or rubber powder, and its purpose is to improve the purity of the rubber powder and the quality of the recycled rubber products. The machine is based on the specific gravity difference between glue powder and fibre, and under the action of airflow, the airflow speed inside the body is changed by adjusting the angle of the air blade plate, so as to achieve high-precision separation.

How these equipments are configured into a complete crushing and grinding production line needs to be flexibly configured according to the specific needs of customers. If you have the need in this regard, you can contact us at any time.