Wood shredder: the core power of wood resource recycling

In today's era of focusing on environmental protection and sustainable development of resources, wood shredder, as a key mechanical equipment, is playing an increasingly important role. It brings innovative solutions to the wood processing industry and related resource recycling fields, effectively promoting the recycling of wood resources and reducing the pressure of waste on the environment.

First, the working principle of wood shredder

Wood shredder mainly relies on strong mechanical power and unique knife structure to realize the crushing of wood. Its core working parts usually include a high-speed rotating spindle and various types of knives installed on the spindle, such as sharp alloy steel blades. When the wood is fed into the inlet of the shredder, driven by the spindle, the knives rotate at a very high speed and interact with the wood. Through the combined effect of various forces such as cutting, tearing and squeezing, the wood is gradually broken into smaller pieces or granular materials. Different types of wood shredders may differ in the design and arrangement of the knives and the power transmission system, but the overall objective is to efficiently convert wood of various shapes and sizes into material forms suitable for subsequent processing or reuse.

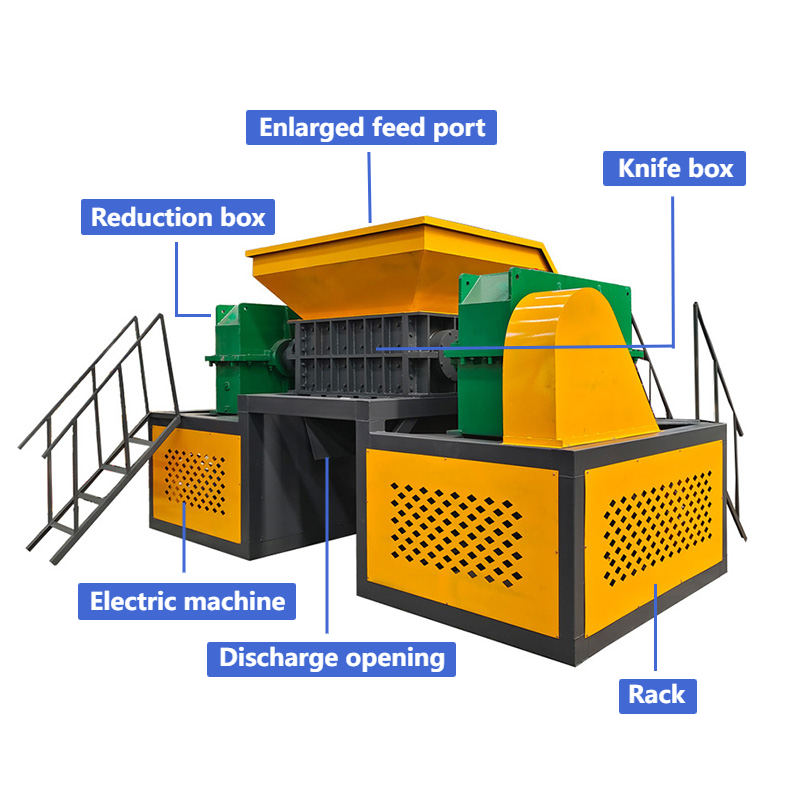

Second, the structural composition of the wood shredder

- Feeding system: the design of the feeding port takes full account of the diversity of wood, with a large opening size, can accommodate different lengths, diameters and shapes of wood raw materials, so as to facilitate the smooth entry of wood into the shredder. Some feeding systems are also equipped with auxiliary devices such as conveyor belts or feed hoppers to improve the efficiency and stability of the feed to ensure that the wood can be continuously and evenly transported to the shredding chamber.

- Shredding Chamber: This is the key working area of the wood shredder, and its internal structure is strong and durable, able to withstand the huge impact and friction generated in the process of wood crushing. The walls of the chamber are usually made of high-strength wear-resistant materials to extend the service life of the equipment. Inside the shredding chamber, the knives are installed on the main shaft, and according to different design concepts, the arrangement of knives can be staggered, spiral, etc., aiming at maximizing the crushing effect on the wood, so that the wood can be fully crushed and processed in the chamber.

- Knife system: the knife is the core component of the wood shredder, its quality and performance directly determines the crushing capacity and efficiency of the equipment. Generally use high-quality alloy steel to make knives, with high hardness, high strength and good wear resistance. Knives have various shapes, common straight knives, curved knives, toothed knives, etc. Different shapes of knives are suitable for different types of wood and crushing requirements. For example, toothed knives are able to better bite into wood fibers for more effective crushing when dealing with hardwoods, while curved knives offer high cutting efficiency when dealing with softwoods or scrap wood. In addition, the knives also have replaceable design, when the knives are worn to a certain extent, they can be easily replaced to ensure the continuous and stable operation of the equipment.

- Power system: a strong power system is a guarantee for the normal operation of the wood shredder. Usually use the electric motor as the power source, the power of the motor according to the specifications of the equipment and processing capacity, from the smaller power for small wood processing workshop equipment to high-power equipment for large wood recycling enterprises have. The power system transmits the power to the main shaft through belt transmission, gear transmission or direct connection to drive the cutter to rotate at high speed, thus realizing the crushing operation of wood. In order to ensure the stability and reliability of the power output, the power system is also equipped with a series of protection devices, such as overload protection, short circuit protection, etc., to prevent damage to the equipment due to unforeseen circumstances.

- Discharge system: The crushed wood materials are discharged through the discharge system. The design of the discharge port can be adjusted according to the actual demand, such as controlling the size of the discharged material, discharging speed and so on. Some discharge systems are also equipped with screening devices, which can sort and collect the crushed wood according to different particle sizes for further processing or utilization. In addition, the discharging system can also be connected with conveying equipment to transport the crushed wood directly to the designated storage area or to the equipment of the next processing procedure, so as to improve the automation of the whole production process.

Third, the advantages and development prospects of wood shredder

Advantage

- High efficiency and energy saving: modern wood shredder adopts advanced technology and optimized design, to ensure high crushing efficiency at the same time, can effectively reduce energy consumption.

- Environmental protection and emission reduction: the wide application of wood shredder helps to reduce the pollution of wood waste to the environment. By converting wood waste into reusable resources, it reduces the amount of waste to be landfilled or incinerated, and reduces greenhouse gas emissions and the risk of pollution to soil and water.

- High resource utilization: The ability to process various wood wastes into valuable products or raw materials greatly improves the overall utilization of wood resources. Whether it is recycling within the wood processing industry or cross-industry resource integration, it provides strong support for the sustainable development of wood resources.

Prospects for development

- With the increasing awareness of global environmental protection and the concept of resource recycling in-depth, the market demand for wood shredder will continue to grow. In the future, wood shredder is expected to further innovate in technology, such as the development of more efficient and durable tool materials and advanced crushing technology to improve the overall performance of the equipment.

As an important equipment in the field of wood resource recycling, wood shredder is showing a broad development prospect with its unique working principle, perfect structural composition, wide range of applications and significant advantages. In the future development, it will continue to play an important role in promoting the cause of environmental protection and sustainable utilization of resources, and become an important force in building a green, circular economy.