Wood Shredder: Unlocking the Technological Codes for Efficient Wood Crushing

Time:2024-12-02

Working Principle

- The wood shredder mainly reduces the size of materials by shearing, tearing and extruding. When it works, the material first through the feeding system into the shredding box body, the box body carries a shredding blade, the push box will push the material to the blade near, and then the material in the shredding blade tearing, extrusion, shear and other combined effect, be torn into small pieces of material, and finally discharged from the sieve mesh holes.

- Different types of wood shredder will have some differences in the specific working principle. For example, single shaft shredder, is driven by the motor through the reducer knife roller high-speed rotation, so that the knife installed in the knife roller on the knife particles and the fixed knife to form a cutting, the material after a cutting, if the size of the screen is smaller than the aperture, then from the mesh out of the material, or else the material will be in the knife box for the second or more cuts until the size of the material until the material can be discharged!

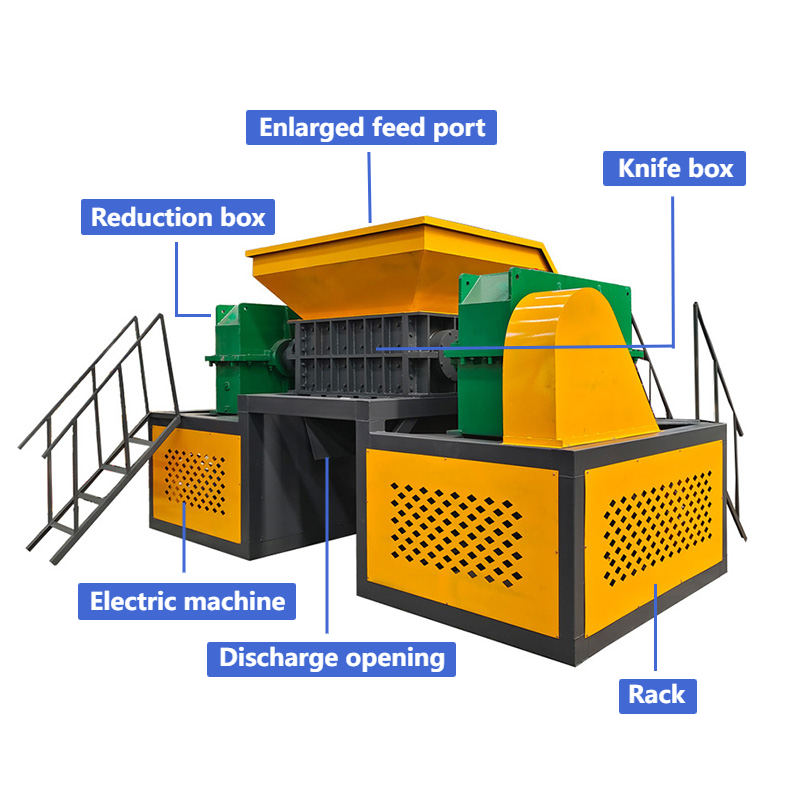

Structural Components

- Blade: It is one of the key parts of wood shredder, the main blade is usually made of special alloy steel by special process, which has the characteristics of good wear resistance and high strength, and the auxiliary blade is usually made of mould forging parts. The thickness of the blade and the number of claws can be adjusted and replaced according to different materials, in order to adapt to a variety of wood and other materials shredding needs 124.

- Knife Shaft: Knife shaft is the part to install the blade, and its quality and strength have an important impact on the performance and stability of the equipment. The knife shaft of some wood shredders is made of high-quality steel with high hardness and toughness, capable of withstanding large torque and impact 124.

- Box: The box is the part that holds the blades and materials, and is generally made of thick plates with high strength and rigidity, which can resist high torque and is sturdy and durable, and can ensure the stability and safety of the equipment in the working process 111.

- Feeding system: It is responsible for conveying the materials to the inside of the shredding box, and the common feeding methods are belt conveyor, screw feeder, etc. The feeding system should be designed to ensure that the materials are conveyed to the inside of the shredding box. The design of the feeding system should ensure that the materials can enter the box evenly and stably to improve the shredding efficiency and quality 159.

- Pushing device: The pushing box, driven by hydraulic or mechanical device, pushes the material to the blade, so that the material can fully contact with the blade to ensure the shredding effect. The pressure and stroke of the pushing device can be adjusted according to the nature of the material and shredding requirements 159.

- Sieve mesh: the sieve mesh is located at the outlet of the box, and its function is to control the particle size of the material. Different specifications of the screen can meet the requirements of different users on the size of the material, and the screen is easy to dismantle and simple, easy to clean and replace 124.

- Power system: provide power for the wood shredder, usually driven by motor or diesel engine. The power of the power system depends on the model and production capacity of the equipment, generally speaking, the higher the power, the stronger the shredding capacity of the equipment 125.

- Control system: the use of microcomputer (PLC) automatic control, with start, stop, reverse and overload automatic reversal and other control functions, to achieve automated operation and protection of the equipment, improve the reliability and safety of the equipment, but also to facilitate the operator to monitor and adjust the

Previous Article: HaiShiHong Briefing: Scrap Iron and Steel Shredder